Intrinsically safe (IS) equipment is a specialized category of electrical and electronic devices designed to operate safely in hazardous environments, where the presence of flammable gases, vapours, dust, or other potentially explosive atmospheres could pose a significant risk. These environments are typically found in industries such as oil and gas, petrochemicals, mining, pharmaceuticals, and many others. The primary goal of intrinsically safe equipment is to prevent the release of electrical or thermal energy that could ignite the surrounding explosive atmosphere.

- Hazardous Environments: Hazardous environments are classified into different zones or classes based on the types of hazardous substances present and their likelihood of causing an explosion. These classifications are typically defined by regulatory bodies like the National Fire Protection Association (NFPA) or the International Electrotechnical Commission (IEC).

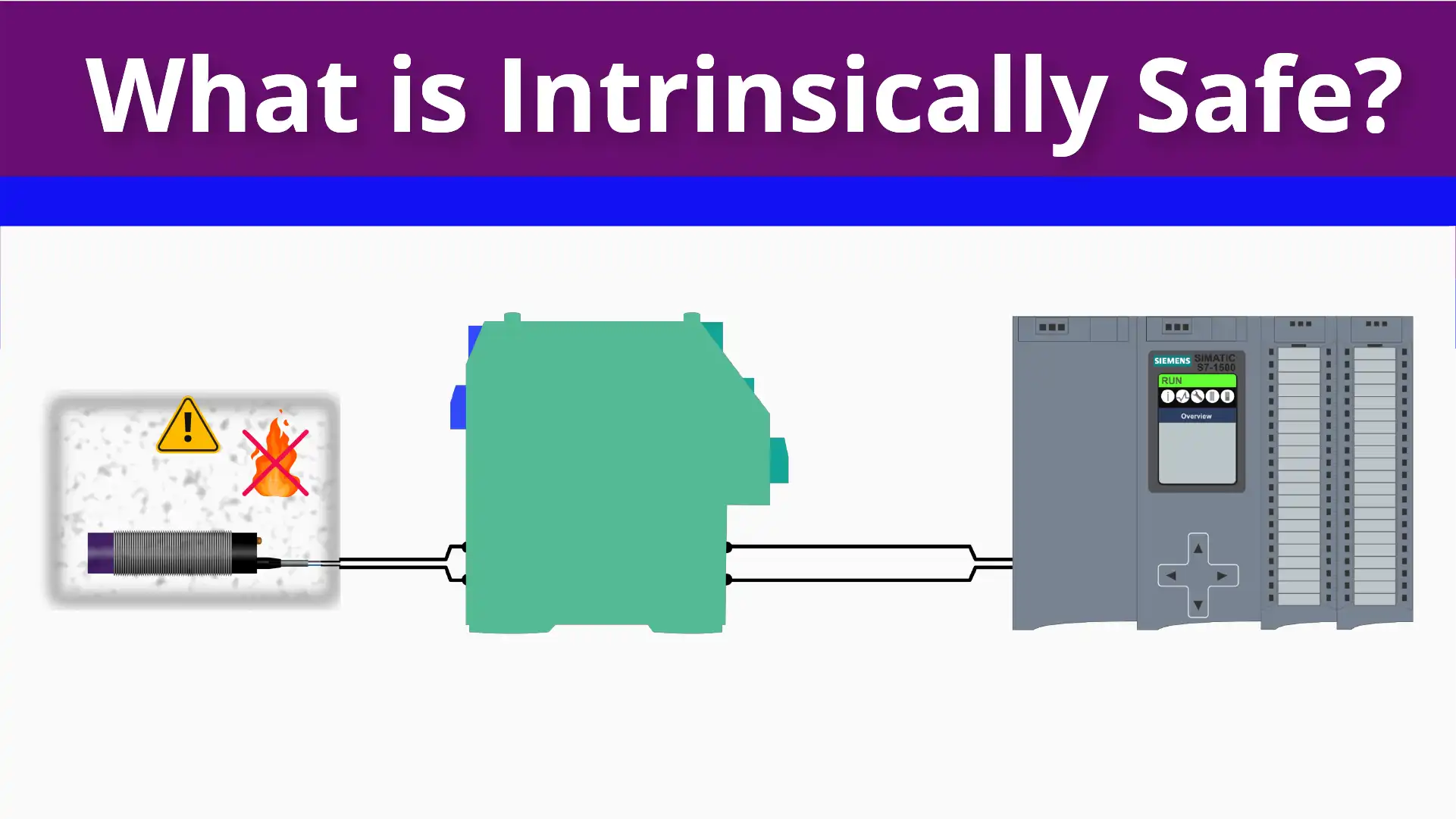

- Principle of Intrinsic Safety: Intrinsic safety relies on the principle of limiting the electrical and thermal energy in a circuit to levels below what can cause ignition. This is achieved through a combination of factors, including limiting voltage, current, and energy in the electrical circuits.

- Components of IS Equipment:

- Intrinsically Safe Barriers: These are devices that are often used to limit the energy supplied to the hazardous area. They act as a safety barrier between the control equipment and the potentially explosive environment.

- Intrinsically Safe Field Devices: These are the instruments and sensors located within the hazardous area that measure and control various parameters. Examples include pressure transmitters, level sensors, temperature detectors, and more.

- IS Control Systems: These are the controllers and other electronic equipment that are specifically designed to operate in intrinsically safe environments.

- Certification and Standards: Intrinsically safe equipment must meet stringent safety standards and undergo rigorous testing to ensure that they do not pose a risk of ignition in a hazardous area. Common international standards include ATEX (in Europe), IECEx, NEC (National Electric Code) in the United States, and various regional standards. Compliance with these standards is crucial for ensuring safety.

- Intrinsically Safe Circuits: Intrinsically safe circuits are designed with specific parameters to ensure safety. This includes limiting voltage, current, and power levels to prevent the generation of sparks or heat that could ignite the hazardous atmosphere.

- Control of Energy: Intrinsically safe equipment often incorporates energy-limiting devices such as resistors and diodes to control electrical energy and reduce the risk of ignition.

- Safety in Operation: IS equipment is designed to be simple to operate, with minimal user intervention. This helps minimise the risk of incorrect configuration or usage that could compromise safety.

- Maintenance and Repair: Maintenance and repair of intrinsically safe equipment must also adhere to strict procedures to ensure that the safety features are not compromised during service or replacement.

- Benefits of Intrinsically Safe Equipment:

- Enhanced Safety: The primary benefit is safety. By using IS equipment, the risk of explosions in hazardous environments is significantly reduced.

- Reduced Maintenance Costs: IS equipment often requires less maintenance because it is designed for simplicity and reliability.

- Lower Insurance Costs: Industries that use IS equipment may benefit from reduced insurance premiums due to their commitment to safety.

- Applications: Intrinsically safe equipment is used in various applications, including process control, data acquisition, and monitoring in industries such as oil and gas, chemical processing, pharmaceuticals, mining, and more.

Intrinsically safe equipment is essential for ensuring safety in environments where explosive atmospheres are a concern. By adhering to strict design, certification, and operational standards, IS equipment minimises the risk of ignition and plays a critical role in protecting both people and property in hazardous settings.

Some examples

Intrinsically safe equipment encompasses a diverse array of devices tailored for use in hazardous environments. These devices ensure the safety of operations in potentially explosive atmospheres. Examples of such equipment include intrinsically safe barriers, which limit electrical energy to safe levels, pressure transmitters for measuring pressure in the presence of flammable substances, level sensors for monitoring liquid or solid levels in tanks, flow meters to measure fluid flow safely, temperature sensors for monitoring temperature in explosive atmospheres, and gas detectors that alert to the presence of flammable gases. Additionally, intrinsically safe solenoid valves control fluid flow, HMI panels display and interact with process data, and PLCs are designed for control in hazardous areas. Emergency shutdown systems provide rapid response during emergencies, while motor starters and drives manage motors safely. Wireless communication devices facilitate secure data transmission, and intrinsically safe cameras enable visual monitoring. Signal conditioners convert sensor signals, gas analyzers monitor composition, LED lighting provides safe illumination, radar level sensors offer precise level measurement, and portable gas detectors are handheld devices for on-the-go monitoring. Fibre optic data links allow optical data transmission in explosive environments, and grounding and bonding equipment prevents static discharge and ensures proper grounding. These examples highlight the versatility and critical role of intrinsically safe equipment in industries where safety is paramount.

What about mobile phones?

Mobile phones, in their standard form, are not intrinsically safe. They are not designed to operate in hazardous or explosive environments, and using a regular mobile phone in such conditions can pose a safety risk.

Intrinsically safe mobile phones are specially designed and certified for use in hazardous environments. These intrinsically safe mobile phones are built with features and components that prevent them from generating sparks, heat, or electrical energy that could ignite flammable gases, vapours, or dust. They typically have robust casings, non-sparking batteries, and limited energy in their circuits.

These specialized intrinsically safe mobile phones are used in industries such as oil and gas, chemical processing, mining, and others where explosive atmospheres may be present. They allow for communication in these environments without compromising safety. If you are working in such an environment, it is crucial to use intrinsically safe communication devices to ensure the safety of personnel and equipment.

Frequently Asked Questions (FAQ) on Intrinsically Safe Equipment

What is intrinsically safe equipment?

Intrinsically safe (IS) equipment is specially designed electrical and electronic devices that are engineered to operate safely in hazardous environments where the presence of flammable gases, vapours, dust, or other potentially explosive atmospheres is a concern.

Why is intrinsically safe equipment necessary?

IS equipment is essential in hazardous environments to prevent electrical or thermal energy from igniting the surrounding explosive atmosphere. It reduces the risk of explosions and protects both personnel and property.

Where are intrinsically safe equipment commonly used?

IS equipment is commonly used in industries such as oil and gas, petrochemicals, mining, pharmaceuticals, chemical processing, and any setting where potentially explosive atmospheres exist.

How does intrinsically safe equipment achieve safety?

IS equipment follows the principle of intrinsic safety, which involves limiting voltage, current, and energy in electrical circuits to levels below what can cause ignition. This is achieved through design, certification, and operational standards.

What are some common examples of intrinsically safe equipment?

Common examples include intrinsically safe barriers, sensors (pressure, temperature, level), control systems, and communication devices specifically designed for hazardous environments.

How are intrinsically safe circuits designed?

Intrinsically safe circuits are designed with specific parameters to ensure safety. This includes using energy-limiting components such as resistors and diodes to control electrical energy and prevent the generation of sparks or heat.

What are the certification and safety standards for intrinsically safe equipment?

IS equipment must comply with international standards such as ATEX (in Europe), IECEx, NEC (National Electric Code) in the United States, and various regional standards to ensure safety.

How do you maintain intrinsically safe equipment?

Maintenance and repair of IS equipment should follow strict procedures to ensure that safety features are not compromised during service or replacement. Technicians must be trained in handling IS equipment.

What are the benefits of using intrinsically safe equipment?

The benefits of IS equipment include enhanced safety, reduced maintenance costs, and the potential for lower insurance premiums due to the commitment to safety.

Can intrinsically safe equipment be used in any hazardous environment?

IS equipment is suitable for specific hazardous environments with classified zones or classes. It is important to consult with experts and regulatory bodies to ensure that the right type of IS equipment is chosen for a particular environment.

Is intrinsically safe equipment expensive?

While IS equipment may be more expensive initially, it can lead to cost savings in the long run due to reduced maintenance and insurance costs. Safety is a priority in industries with potentially explosive atmospheres.

Are there any limitations to intrinsically safe equipment?

IS equipment may have limitations in terms of the range of available devices and potential restrictions on system complexity. It may not be suitable for all applications, so a thorough hazard analysis is necessary.

Can intrinsically safe equipment be used in areas without explosive atmospheres?

Yes, intrinsically safe equipment can be used in non-hazardous areas as well. However, it is generally used in hazardous locations to ensure safety.

How should I choose the right intrinsically safe equipment for my application?

It’s crucial to consult with experts and follow local regulations and standards when selecting IS equipment for your specific application. This helps ensure that the chosen equipment is appropriate and safe for the intended use.